The VSR Project: Building my own Rifle - Part 2

2. The piston was also not a stock piston but unidentified brand again, however, the spring guide had snapped. At the base, this had broken completely and it was in two parts (and covered in a lot of lube). So a new spring guide was needed.

3. We also saw that the cylinder head was the wrong one to match with the hop-up unit that was already inside the rifle so this had to also be replaced.

We daren’t take the VSR10 apart any more as I wasn’t at home and didn’t want to lose any parts in transporting it home. I gave it a good clean when I got home and decided to take the hop-unit out and have a look inside. Which would’ve normally been straightforward but not for me.

4. I couldn’t get the hop up unit out. Where the screw goes in from the receiver to the barrel, the previous owner had screw it the wrong side which had no allocated slot. However, they did this up so tight that it caused an indent in the outer barrel which meant the hop-up unit couldn’t slide out. I had to result in sanding the outer barrel down on the inside in order to get it out.

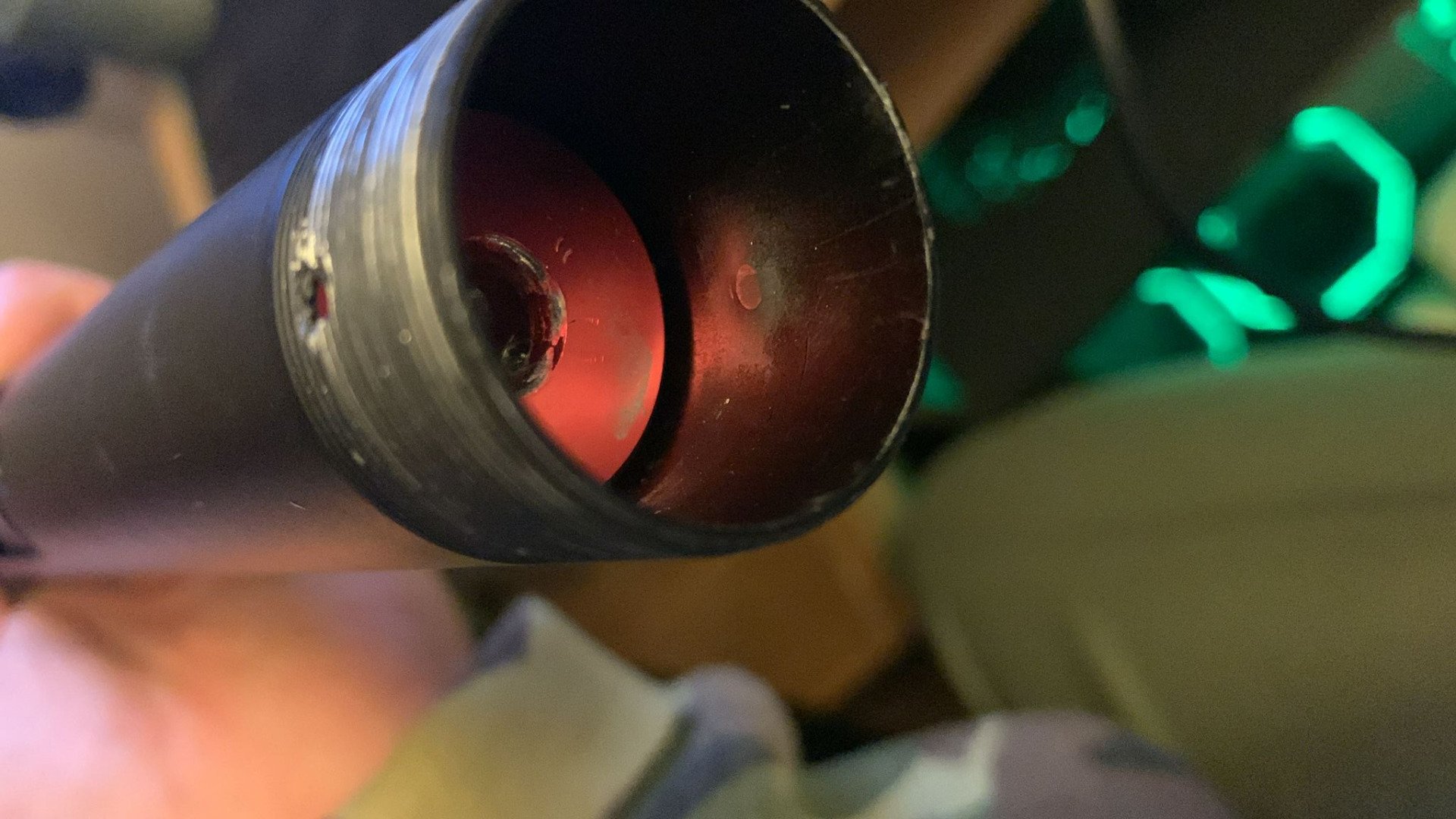

I finally managed to get the Action Army hop-up unit out and take a look. It had a Maple Leaf 70 degree bucking inside and an unknown nub. The bucking didn’t look in good condition at all with a couple of tears so this needed replacing for sure. The inner barrel was in an appalling state.

5. They had tried to create an unbridged barrel from the bridged stock one. Where they had cut it, they had made it really rough and the barrel just wasn’t in a great condition overall. So a new one was needed.

From all these issues, and with the help of Stip the Sniper, we’d come up with a list of new parts needed for this VSR10 to become a well working gun again. The list was:

· Cylinder head

· Inner barrel

· Body screws

· Guide rings

· Spring guide

Stip was kind enough to let me have some spares he had sitting around so he provided me with the cylinder head, inner barrel and spring guide. A mutual friend of ours, Mr Toone, was able to get hold of some body screws for the final part of when I piece the rifle back together. The guide rings were sourced from Longbow.

I found this quite frustrating how much needed replacing and how someone could let this RIF get into this state. It really tested my patience each time I found something wrong and was surprised that this sniper was able to function.

Next steps will be to gather all parts that need replacing and to begin putting together. This will allow me some time to gather some more patience before beginning on this. I'm looking forward to fitting the new parts and learning how the sniper works properly.